Capacitive sensing options are not uncommon today, but many offer limited off-the-shelf capability. One of Cirque's most unique advantages is our ability to build custom solutions for our customers. Our technology is developed completely in-house, which means we can bring together chip designers, firmware developers, mechanical engineers and sensor designers to tackle customer projects. And since all of these resources are located under one roof, we can do this with speed and agility.

Unique Features

Does your application call for proximity sensing of a user's hand above the surface of a game controller? Or a special sensor material can be fit into the frame of augmented reality glasses? Cirque has worked on many solutions like this to extend the idea of whats possible with capacitive touch.

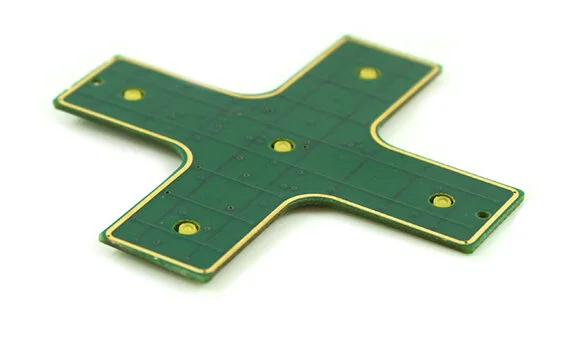

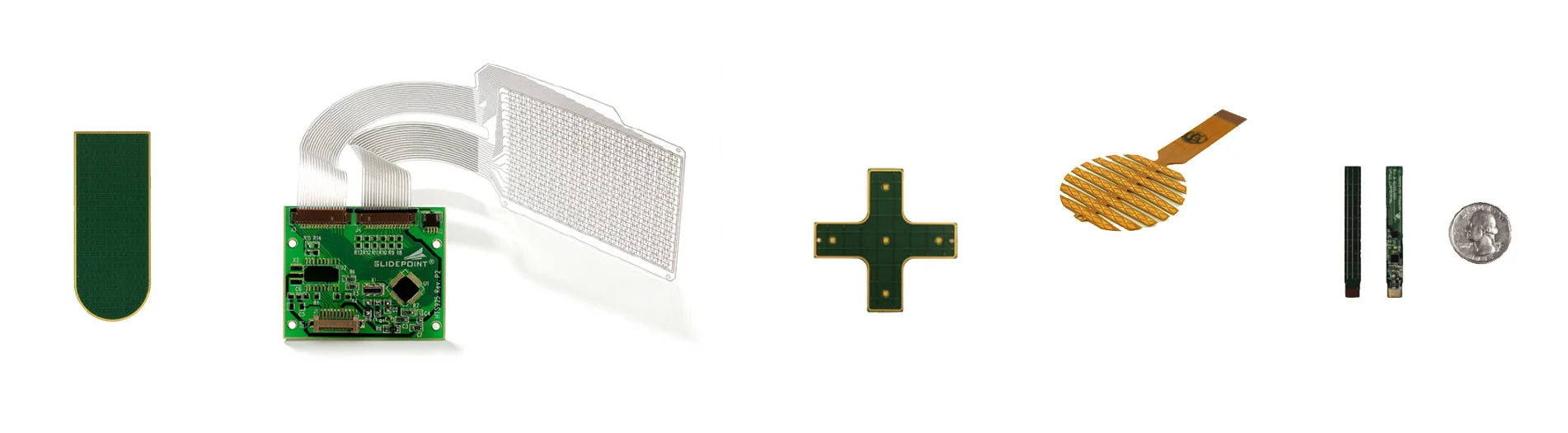

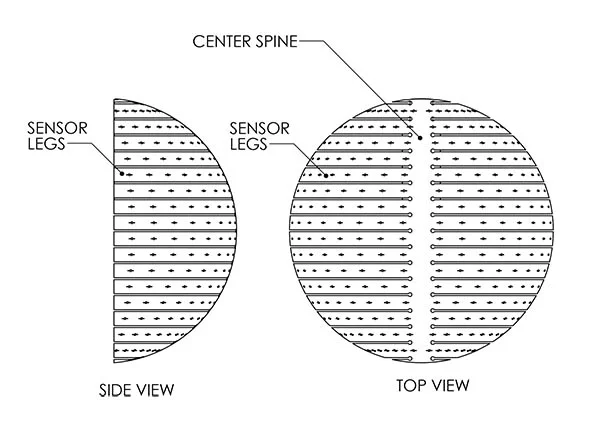

Flexible 3D Designs

Sometimes a project requires something beyond a standard flat rectangular touch sensor. Cirque has developed specialized techniques for enabling touch sensing in almost any industrial design. Flexible curved sensors, asymmetrical shapes, thick cover layers and many more implementations are possible.

Rapid Proof of Concepts

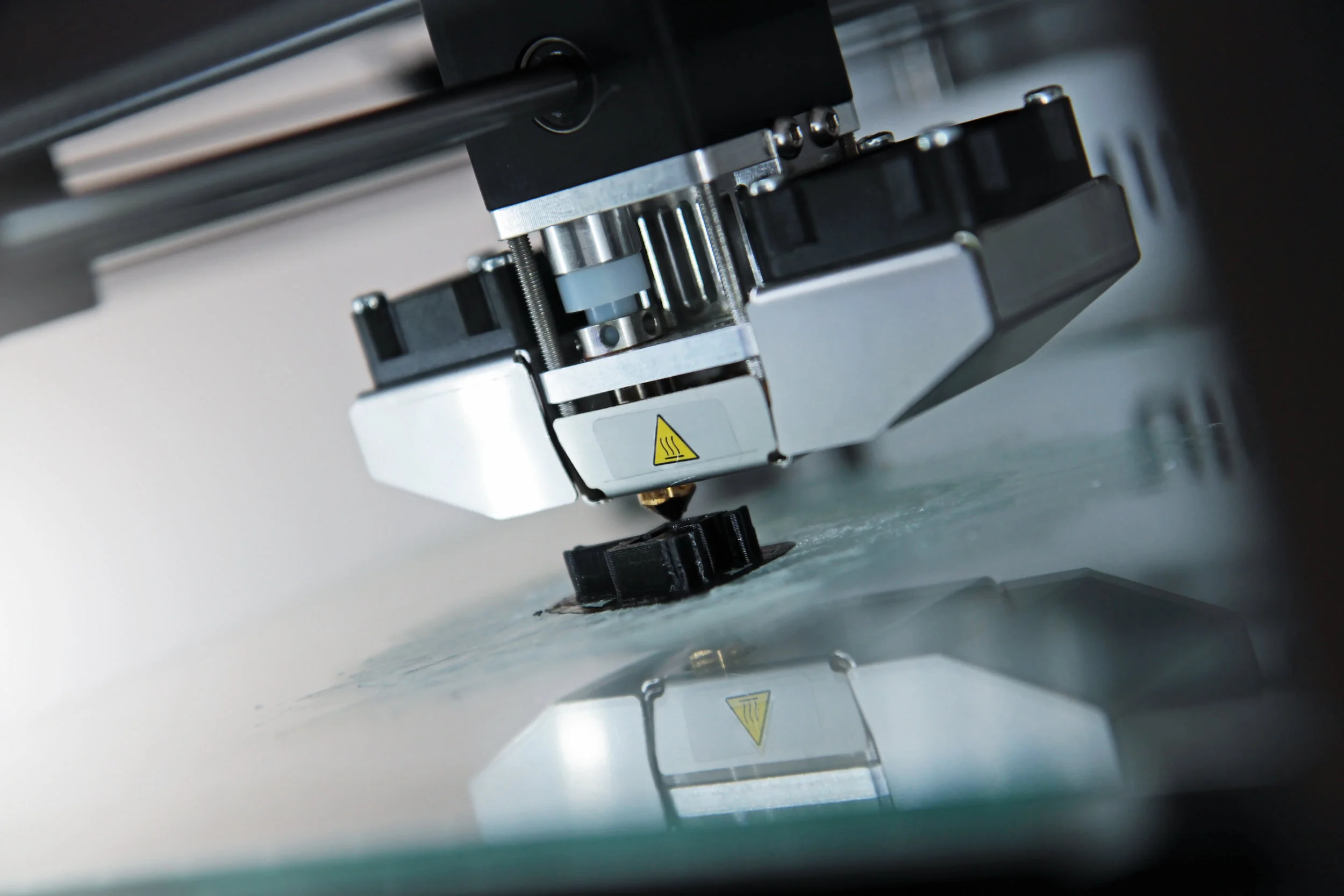

The Cirque development team, from IC design to mechanical engineering is located at one location. So when a customer has a specialized need that requires using a new chip features, we can walk down the hall to discuss with the IC design team, rather than waiting for a response from an office a continent away. Extensive 3D printing capability and many years of experience building rapid prototypes enable quick proof of concepts for your project.

Check out some of the products that feature Cirque custom solutions.